With the patented two camera system, the Camsizer gives the most reliable results for size and shape on the market. Catalysts are more than just rods and cannot be assumed to be special, making the Camsizer the ideal tool for the job!

Quality control of catalysts with the Camsizer P4

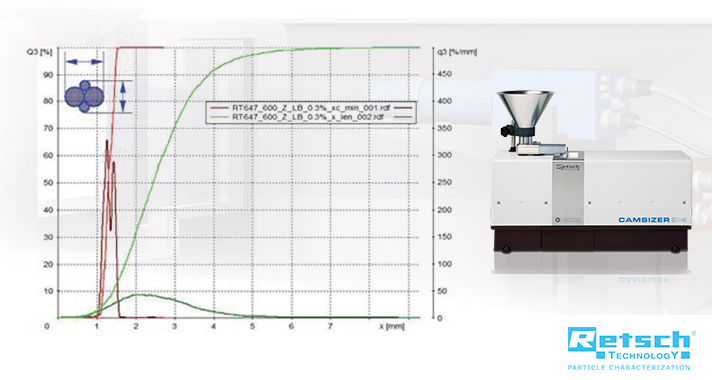

The analysis of size and shape plays an important role for the quality control of catalysts. Sieve analysis is often used for this, however, it only provides the required size information for spherical particles. Rods, for example, pass the mesh with a particular orientation which makes it impossible to clearly separate breadth and length values.

Catalysts are widely used as an important auxiliary material in the pharmaceutical and chemical industry. They are able to accelerate chemical reactions by lowering the activation energy, i.e. they change reaction kinetics.

Thus, using catalysts in industrial processes has the advantage of higher productivity combined with less energy consumption. In many processes a mixture of liquid or gaseous raw materials (e.g. petroleum) is transformed in a reactor with solid catalyst material.

Depending on the desired reaction, catalysts of different materials such as ceramics, alumina, metal or alloys are used. To save costs, inexpensive substrates can be coated with the actual catalyst (e.g. platinum or rhodium).

The active surface as well as the form of the catalysts is crucial for their efficiency. It is important that sufficient free volume is available for the reactants. Moreover, the counter pressure built up by the catalyst must not be too high. Spherical, comb-shaped or rod-shaped geometries have proven to be especially suitable. The rod-shaped catalysts have different shapes; their profiles can have an ellipsoid, trilobe or quadrulobe shape.

Dynamic Image Analysis

With over a thousand instruments in operation worldwide, the CAMSIZER P4 is the most successful tool for particle size and shape analysis of dry, flowable bulk goods with dynamic image analysis. Due to its wide measuring range of 20 μm to 30 mm and the excellent compatibility to sieve analysis, the CAMSIZER P4 is a powerful alternative to traditional sieving.